Role Segmentation: Strengthening the Machine

by Chasidy Rae Sisk

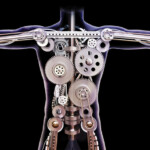

A machine is defined as “an apparatus using or applying mechanical power and having several parts, each with a definite function and together performing a particular task.” Machines work by accepting an input, transforming or modifying it in some way and then releasing the output of its efforts.

Most discussions and examples of a “machine” will include references to automobiles, a vital piece of the collision repair industry, yet there’s an even more important machine that plays a role in this field: the shop itself!

Most discussions and examples of a “machine” will include references to automobiles, a vital piece of the collision repair industry, yet there’s an even more important machine that plays a role in this field: the shop itself!

Each repair facility (apparatus) requires several parts (employees) to use or apply their power to function together and perform a particular task. Following a collision, the auto body shop inputs a damaged car, transforms it during the repair process and outputs a vehicle that has been safely restored to its pre-accident condition.

While a typical shop employs an estimator, body technician and painter, some of these “machines” have found ways to increase efficiency, profitability and even employee morale by implementing the concept of strategic role segmentation. By gleaning insights from successful strategies used in other industries, savvy shop owners have identified ways to utilize these techniques to strengthen their businesses by adapting to future trends and promoting the growth of employees’ unique skills, which in turn, improves workflow and overall productivity.

How did they accomplish all of that exactly? By breaking that structure down into more specific segments. A segmented collision shop has people devoted to specific roles, such as blueprinter, customer service representative (CSR), glass technician, structural technical, mechanical technician, ADAS tech, dedicated parts team, refinish prepper, refinish technician and a diagnostic technician.

Why have some shops decided to go this route?

“Originally, we had traditional estimators who ran back and forth around the shop; they wrote the estimate, sold the job to the customer and captured the keys, followed the car through the repair process from start to finish and dealt with the insurance claim,” Burl Richards recalls about Burl’s Collision (Henderson), the shop he recently sold after 28 years. “Our estimates were very inconsistent because different people wrote them differently, so we’d get more pushback from insurance companies. We wanted to create more continuity in our repair plans.

“We found that communication was a major challenge throughout the entire process. There was an obvious disconnect between the estimator, the customer, the technician and the painter, so at every meeting, I would stress that they needed to talk to one another and we’d make small changes to try to improve things. At one point, my production manager asked if we would ever stop changing, and I told him, ‘Sure, when we get it right!’ Shops will probably always need to make some adjustments because of how much our industry constantly advances, but the need to make large changes slowed down about eight years ago when we started implementing role segmentation.”

That division of responsibilities was so successful that Richards plans to roll it out in his three remaining shops: Doug’s Paint & Body (White Oak), Fishburn’s Collision Center (White Oak) and Laserline Collision Center (Lindale).

For Eric McKenzie (Park Place Dealerships; Dallas/Fort Worth), segmentation is just the way it is because it makes the most sense. “The segmentation we have at Park Place and at my previous dealer shop were always in place, so it is the way I learned the business, and it has worked for both companies. It has always worked well as designed.”

So, how does it work?

The process of role segmentation begins from the moment the car enters the shop. Rather than having an estimator who deals with customers, insurers and technicians – a job that can be overwhelming for even the most experienced industry professional – these roles can easily be divided into a CSR and a repair planner.

“When a customer walks in, the CSR writes the estimate and takes photos if needed,” Richards explains. “They also educate customers on the claims process, helping them understand that the estimate is just that – an estimate – and an accurate repair plan requires vehicle disassembly.”

Once the car entered the shop, the team at Burl’s Collision Center would pre-wash the car, take a video to identify any existing damage and pre-scan the vehicle before sending it to the DFR (disassembly for repair) team. “Using the initial estimate provided by the insurer as a basis to write the supplement(s), one of our repair planners would review the car with the technician after disassembly to research all the OEM repair procedures and identify any ADAS features so they could write a thorough supplement that included all the processes and procedures necessary to properly repair the vehicle. The repair planner sent the supplement to the CSR who forwarded it to the insurance company and informed the customer that a repair plan had been submitted to their carrier.”

The car was then held until the insurer greenlit the repair plan; not surprisingly, this often took multiple supplements. When the approval finally came through, parts could be ordered, and upon their arrival, the body tech could begin the repairs. Then, the car would go to the paint department for refinishing before moving to the painter’s helper for nib and polish.

One of the most important components to each step of the repair was the quality control process, according to Richards. “At each step, the repair planner would review the progress with the technician, painter, etc. to sign off on the work performed. We had a lot of QC processes in place which enhanced our overall efficiency since we didn’t have to backtrack vehicles because a mistake was made earlier in the process. Once the vehicle was restored, the repair planner would communicate any final supplements to the CSR who would submit it.”

Another vital way that Burl’s Collision Center improved communication took shape first thing each morning in the shape of a daily production meeting. “All the CSRs, repair planners, body techs, painters, painters’ helpers and management team would spend just 10 minutes discussing all the jobs for the next three to five days so everyone had an update on where each vehicle stood in the process. The updates included information like where the parts were and reminders when sublets were necessary. Those meetings were crucial to our success.”

Training is essential in all shops, but role segmentation allows individuals to specialize and focus their learning efforts in specific areas. It has also proven beneficial for shops seeking OEM certification. “Several of the OEMs that manufacture electric vehicles have specific body and mechanical technician training requirements,” McKenzie shares. “Several other luxury OEM certifications require role specific training for estimators, body technicians and refinish technicians.”

“All the training we did and seeking to understand how the manufacturers want their vehicles performed really took us over the top,” Richards agrees. “Burl’s was the most certified shop in East Texas with 23 certifications, and we were really conscientious of the importance of performing a proper repair.”

All those changes made a huge difference in improving consistency as desired, but the impact extended to improving productivity, which enhanced profitability, and it also had a positive effect on the shop’s culture. “With the segmentation we have, it is both efficient and profitable,” McKenzie stresses. “Employee morale has always been good as well. Role segmentation seems to be more prevalent in the dealer collision center environment, and we group the roles into teams for each estimator to keep communication and teamwork as cohesive as possible and that helps maintain an overall positive shop culture.”

“The consistency creates clear expectations not only for the staff but also for insurers, but more importantly, segmentation allows everyone to focus on what they do best,” Richards insists. “The people who excel at communication do a great job as a CSR, and those who enjoy research and are more technologically inclined make great repair planners.”

Of course, any major change is bound to face some reluctance. McKenzie acknowledges this was the case when his shop decided to stop subletting glass repairs in favor of having the body technicians perform the work. “There was some resistance at first, but as soon as the technicians went to OE glass class, they were more than willing to take on the task.”

For Richards, it took some trial and error to identify employees’ strengths. “We rotated people into different roles and offered a lot of training. But I think the reason this change was accepted and became so successful was related to my belief in empowering employees to have some say in how it’s all done; they’re the ones who do the job every day, so I’m always willing to listen to their suggestions because my goal is the end result, regardless of how we get there. If people resisted a change, we would discuss how to improve it, but I always told them, ‘Don’t come to me with a problem unless you also have a solution.’ They had to suggest a way to fix it.

“I’ll never claim that it was a perfect machine, but segmentation roles led to the best way of running a shop that I experienced in my 28 years at Burl’s. You have to be willing to look outside the box and try something different. If you do things the same way that everyone does them – the way they’ve always been done – you’ll never be anything more than average. But I don’t want to be average at anything I do; I want to set myself apart! Embracing concepts that make a huge difference has always allowed my shops to do exactly that, making us stronger and more successful.”

Want more? Check out the November 2024 issue of Texas Automotive!